REDUCING CONSUMPTION; REUSING RESOURCES

KONBSGBERG AUTOMOTIVE'S (KA'S) NORMANTON PLANT CUT THEIR OIL CONSUMPTION BY 90%, AND RE-USED VALUABLE RESOURCES

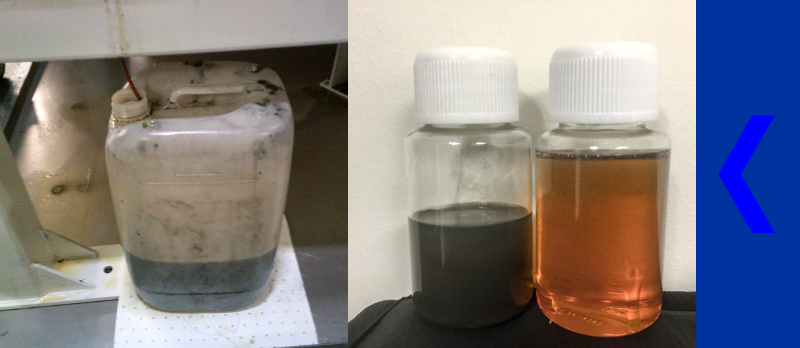

At the KA Normanton plant, Ep 150 oil is used as a lubricant for machinery for wire braiding. The excess oil from the process is collected and disposed off. All braiding machines account for 700 liters of waste oil per week, resulting in approximately 35.000 liters of waste oil per year.

This does not only negatively impact the environment, but it is a significant cost factor as well. With KA’s sustainability targets in mind, the Normanton plant set out for a solution and implemented a state-of-the-art Re-use process.

The collected waste oil, instead of being disposed of, is being filtered using a portable fluid cleansing rig. Lab results have shown that the lubricant properties of the recycled oil match those of new oil. Implementing this process allows KA Normanton to cut the need for new oil by app. 90%, which avoids waste, the purchase of virgin oil and saves costs.

Kyle Selby, Operation Excellence Champion, KA Normanton says: “We are proud of this achievement, and it is not just a win for just KA Normanton. The process can be applied to other plants as well, offering further cost saving potential”.